In industrial settings where hazardous environments are a constant concern, safety is of utmost importance. One device that has gained significant popularity in recent years is the explosion-proof torch. With its robust construction and specialized features, the explosion-proof torch has become an essential tool for numerous industries. In this blog, we will explore the versatility of explosion-proof torches and how they have revolutionized safety measures in industrial workplaces.

What is an Explosion-Proof Torch?

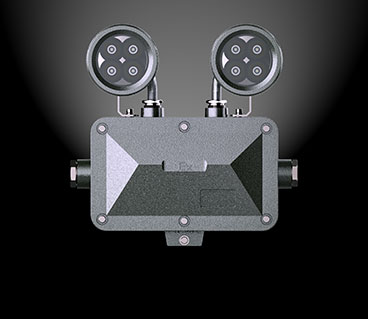

Before delving into the versatility of explosion-proof torches, it is crucial to understand what these devices entail. An explosion-proof torch is specifically designed to function safely in explosive atmospheres. They are engineered to prevent ignition of hazardous gases, vapors, or dust particles, significantly reducing the risk of explosions. These torches are made from durable materials that can withstand rugged conditions and are equipped with advanced safety features.

Applications of Explosion-Proof Torches

The applications of explosion proof torch light extend across various industries, where hazardous environments are a constant. One prominent use is in the oil and gas industry, where these torches are indispensable for maintenance, inspection, and repair work carried out in potentially explosive areas. They are also widely used in chemical plants, refineries, mining operations, and even firefighting scenarios. The versatility of explosion-proof torches ensures their relevance in numerous industrial settings.

Key Features of Explosion-Proof Torches

What sets explosion-proof torches apart from regular torches? These specialized devices come with several key features that ensure their safety and efficiency in hazardous areas. Firstly, explosion-proof torches are typically intrinsically safe, meaning they are constructed with non-sparking materials and are incapable of producing sparks or heat that could ignite flammable substances. Additionally, they often have sealed housings to prevent the entry of flammable gases and dust.

Another important feature is their resistance to impact and temperature extremes. Explosion-proof torches are designed to withstand rough handling, falls, and even minor explosions without compromising their functionality. Furthermore, these torches are equipped with advanced battery technologies, such as rechargeable lithium-ion batteries, ensuring long operating times and reducing the need for frequent battery replacements. These features collectively make explosion-proof torches reliable and durable tools for industrial applications.

Ensuring Safety and Compliance

The use of ex-proof torch light not only enhances safety in industrial settings but also ensures compliance with regulatory standards. Various regulatory bodies have set guidelines and certifications for explosion-proof equipment, ensuring its reliability and effectiveness. In the United States, the National Electric Code (NEC) provides standards for explosion-proof equipment, while the European Union mandates the ATEX directive. By using certified explosion-proof torches, industries can demonstrate their commitment to safety and avoid potential legal repercussions.

In conclusion, the versatility of explosion-proof torches has revolutionized safety measures in industrial settings. These specialized devices enable workers to effectively perform tasks in hazardous environments without compromising their safety. The robust construction, advanced safety features, and compliance with regulatory standards make explosion-proof torches indispensable tools across several industries. As technology continues to advance, we can anticipate even more innovative features and improved performance from explosion-proof torches, further enhancing safety in the industrial workplace.

ATEX/IECEx Standard

ATEX/IECEx Standard

Each member of the SUREALL team works hard to save energy, reduce budget, maximize durability, bring success to every project for every customer. Here are just a few examples of how we've impacted the markets we're proud to serve.View More +

Each member of the SUREALL team works hard to save energy, reduce budget, maximize durability, bring success to every project for every customer. Here are just a few examples of how we've impacted the markets we're proud to serve.View More +

English

English  Español

Español  português

português  русский

русский  日本語

日本語  العربية

العربية  français

français  Deutsch

Deutsch  한국어

한국어  italiano

italiano  Malay

Malay